BOAL Group companies Holland Scherming and Alumat Zeeman have joined forces to introduce two innovative screen components that further optimize energy savings, installation time, and CO2 reduction: Smart Leading Edge and Smart Closing Edge.

Smart Leading Edge: Screen profile with superior light and energy density

The Smart Leading Edge is a new screen profile suitable for all horizontal screens. It ensures an optimal connection to the greenhouse truss. This means superior light and energy density. "Not only the excellent seal is an advantage," says Maarten van Hagen, Sales Manager at Alumat Zeeman. "Thanks to the compact design, there is also less light interception, which results in a higher crop yield. Due to the ingenious design, the Smart Leading Edge has the same rigidity as the current 30mm profile, while it has a slimmer design. To ensure a better seal and faster assembly, the profile is equipped with round instead of flat rubber and the rubber is rolled into the profile instead of pulled.”

In addition to the advantages in performance, the Smart Leading Edge profile also contributes to CO2 reduction. By using less aluminium than the current 30mm profile, the production has a lower ecological footprint. The profile is made of high-quality materials and has a lifespan of at least 20 years. The simple assembly and disassembly also make the product extremely suitable for recycling.

Smart Closing Edge: Fast, sustainable and a perfect solution for a second screen in existing greenhouses

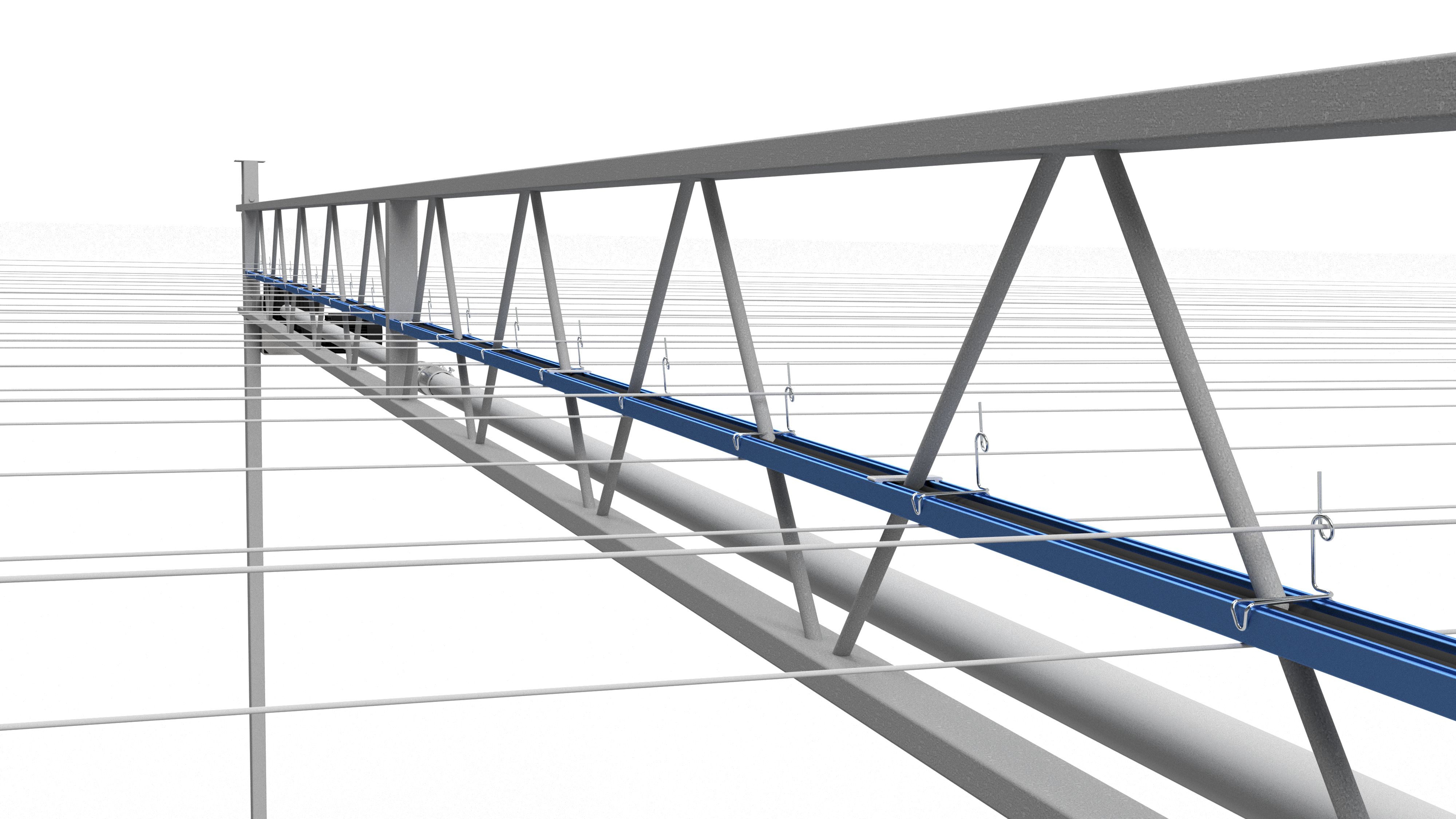

The Smart Closing edge is made of an aluminium profile on both sides of the truss with a rubber seal in between. Combined with the smart leading edge, the smart closing edge ensures an optimal seal. The system offers a number of significant advantages over the existing installation method. From faster installation and optimal sealing to a more sustainable product and a more attractive appearance in the greenhouse.

“We have noticed that the popularity of second, and even third energy screens, has increased enormously in recent years,” says Peter Rense, Commercial Director at Holland Scherming. “More and more growers are seeing the benefits of extra screens and are investing in this energy-saving solution. The addition of a second energy screen yields a considerable return. Not only a significant saving on energy costs, but also an improvement in crop productivity."

Of course, multiple screen systems are already taken into account in new constructions. However, existing greenhouses are often not equipped to install a second screen. “In these greenhouses, we mount a second screen on a wire bed against the bottom of the trellis,” says Peter. “Cloths are mounted around the wire and cut in at the height of the truss. It is a time-consuming job and the seal is not ideal, thus limiting optimal energy saving."

Installation is quick and easy

The new Smart Closing Edge can be placed at any height in the truss span and is clamped around the span. The round rubber ensures a perfect seal and the clamps will keep the profile securely in place. The clamps guarantee that the profile stays securely in place. The Smart Leading Edge also closes seamlessly to the Smart Closing Edge, creating a superior seal for both energy and light, so again the sealing is superior.

See the innovations live at Greentech!

We invite you to discover these innovative solutions in person at the Greentech Exhibition from 11-13 June 2024. Visit Holland Scherming at booth 01.228 and Alumat Zeeman at booth 01.220 to learn more about how the Smart Leading Edge and Smart Closing Edge can transform your greenhouse efficiency and sustainability. Don’t miss this opportunity to see the future of greenhouse technology in action.